The first step in making fire is to burn-in your fire board. Burning-in is the process of making the hole in your fire board that the spindle will fit into. You should have already used your knife point to start a small hole in the fire board. This starter hole should be in the center of the fire board about two inches from either end. When the starter hole is complete you may begin the-burning in process.

BURNING-IN (directions for right handed person):

1. Lay the fire board on the ground with the starter hole to your right.

2, Kneel down on your right knee and place the ball of your left foot firmly on the fire board about two inches to the left of the starter hole.

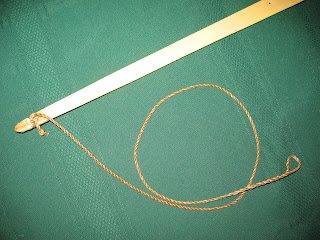

3. Take the bow in your right hand and the spindle in your left hand and wrap the bowstring one time around the spindle about three inches above the pointed end. This may take a few tries. Remember, you have to end up with the bow in your right hand, the string to the left and the pointed end of the spindle pointing down. Pictured below: Proper position of the string around the spindle.

4. Place the pointed end of the spindle into the starter hole. Take the handhold in your left hand and set it over the top of the spindle. Brace your left wrist on the outside of your left ankle so that the spindle won't wobble around when you start to turn it.

5. With your right hand, very slowly begin to move the bow forward and back the full length of the string. Be sure to keep the bow parallel to the ground through the entire length of the stroke. If you saw up and down with the bow it will cause the string to run up and down the spindle and either run off the end of the spindle or pop the spindle out of the starter hole. Pictured below: Turning the spindle to burn in the hole.

6. Hold the handhold onto the top of the spindle with very light pressure. It is a common mistake to apply to much pressure in which case the spindle will become hard to turn, and the bowstring will begin to slip.

7. Once you get the spindle turning properly it should only take a few strokes and you will begin to see a small whiff of smoke as the spindle begins to burn a hole down into the fire board. Do not burn to deeply. One fourth of an inch is plenty. Pictured below: Burned in hole in fire board

NOTCHING THE FIRE BOARD

Now that you have burned in your fire board it is time to carve the all important "notch." The notch is a pie shaped hole that is cut out of the side of the fire board. The notch starts at the edge of the fire board where it is about 1/4 inch wide and tapers to a point at the center of the hole that you have just burned into the fire board. The glowing coal that you will use to start your fire will form in this notch. Pictured below: top, cutting the notch; bottom, the finished notch

PREPARING THE SPINDLE

There is one last thing to do before you actually start the fire. Take your knife and re-sharpen the point of the spindle. Be sure to remove all of the charred wood from the end of the spindle. This step needs to be repeated each time you use the spindle. Charred wood on the end of the spindle will cause the spindle to turn to easily in the hole, and you won't have enough friction to form your coal. Pictured below: Removing char from the end of the spindle

FORMING THE COAL

Now you are ready to form a glowing hot coal with your fire making tools. Be sure and have a double handful of dry, fluffy tinder ready to accept the coal once it is formed.

To begin forming the coal set your fire board and spindle up just like you did to burn-in the hole. The only difference in the set-up is that this time you need to set a dry leaf, thin chip of wood, piece of bark or something under the notch in the fire board. The purpose of this piece of material is to catch the coal as it falls from the notch. You can then pick up the leaf or piece of bark and transfer the coal to your bundle of tinder. Pictured below: Bark placed below the notch in the fire board.

Some people set the fire board down on top of the bundle of tinder so that the coal will fall directly into the tinder. This will work fine as long as the tinder is setting on a perfectly dry surface. But if the surface is the least bit damp, the tinder will suck up moisture like a sponge, and your coal will never turn into a flame.

Now that you are all set up, begin working the bow back and forth just as you did to burn-in the hole. Remember to use very light pressure at first. Take long, fairly slow strokes to warm up the spindle and fire board. As the fire board begins to smoke a little, increase the pressure on the handhold just a little and turn the spindle a little faster. Remember to use the full length of the bow when you are turning the spindle. Don't make the stroke any shorter just because you are moving your hand faster. Pictured below: Fire board and spindle starting to smoke.

The spindle and the fire board should now be smoking heavily and a pile a black, smoldering powder should be filling up the notch. It is now time to sprit for the finish line and form that coal. Apply more pressure to the handhold, (not to much or the string will start slipping). Now, stroke hard and fast, the full length of the bow, about ten or twelve times. Smoke should be pouring off of the spindle and fire board. Pictured below: Lots of black powder and heavy smoke mean the coal has probably formed and is ready to transfer to the tinder bundle.

Stop stroking. Set the spindle and bow aside. Don't get in a hurry. If you have a coal, the powder in the notch will still be smoking and the coal will burn for quite a while. Now take the point of your knife and place it at the top of the notch. Lift the fire board gently as you press the knife point down through the notch. The still smoldering coal should fall out onto the leaf or bark that you placed under the notch. Carefully transfer the coal to the center of your bundle of tinder. Pictured below: top, Using knife point to flick the coal out of the notch; middle, glowing coal on the piece of bark; bottom, transferring the coal to the tinder bundle.

BLOWING THE COAL INTO A FLAME

You would be surprised at how many people can produce a coal and get it into the tinder bundle and then never get the tinder to flame up. Often this is because of moisture, but sometimes it is because of poor technique.

When you have transferred the smoldering coal to the tinder bundle, pick the tinder up very carefully and cup it in your two hands. Very gently fold your hands up so that you bring the outside edges of the tinder bundle up and around the coal like a fluffy nest. Don't press in so hard that you smother the coal or flatten out the tinder. Just nuzzle the tinder up gently around the coal. Now blow softly, not like you're trying to blow out a candle, but softly. The coal should begin to glow a dull red. Blow a tiny bit harder and keep the fluffy edges of the tinder in light contact with the coal. The coal will begin to glow a brighter red, then orange, then yellow and then the tinder will begin to catch the spark and smolder. Pictured below: Blowing on the coal.

When the spark begins to run out into the tinder, hold the tinder bundle out in front of and a little above your face. Turn your head to the side and breathe in. This will keep you from getting a lung full of smoke. Now turn your face back to the smoldering bundle long and steady, not hard, just steady. Turn your head to the side and breathe in. Turn back to the bundle and blow. Be careful because at any moment the tinder bundle will reach critical temperature and burst into flame. When this happens, be ready to pop the blazing tinder into your pre-laid campfire and blow the fire to life. Pictured below: Tinder bursting into flame.